The die-cutting process is a popular manufacturing technique in the packaging industry. It involves the use of dies used to cut soft materials into various packaging designs and shapes.

The ability to produce custom packaging in volume is where the true value of the die-cutting process lies. Die-cut packaging is easier, faster and more cost effective, allowing for the creation of custom packaging on a larger scale.

In this article, we'll explore the die-cutting process and its role in custom packaging.

You will also see.

● Die-cut boxes explained in detail

● How cutting dies are made

●Die-cutting technology

● The FEFCO corrugated packaging category

● Finishing options that complement die-cut box design

Understanding the die-cutting process

A cutting die is essentially a giant cookie cutter that is pressed into the material to form the desired shape of the package.

Die cutting has come a long way from its origins in the shoe industry during the industrial revolution.

Originally designed to aid in the mass production of packaging, die cutting has evolved into a versatile manufacturing process.

Almost any shape, design or pattern can be created using cutting dies.

Customized packaging is produced using custom steel dies and die-cutting machines.

This form of manufacturing allows for mass production of packaging. But more importantly, die-cut packaging ensures precision accuracy.

How are cutting dies made?

The development of cutting die technology and manufacturing techniques ensures the most efficient and accurate die-cut box design. Typically, the package outline is generated by Computer-Aided Design (CAD).

This digital drawing is transferred to a piece of hardwood called a template.

The most sophisticated method of drawing the design on the template is to burn it on the wood surface using a state-of-the-art laser cutter.

The introduction of the laser in this process ensures greater accuracy in drawing on the moldboard.

Cutting dies are made using metal strips called rule or steel rule. The cutting rule is shaped into shape using a rule bender, which bends, cuts and grooves the steel into the desired shape.

Multiple cutting rules can be used in the die cutting process. Each rule has its own function and purpose, depending on the complexity of the package.

Some of the most common rule options are.

● Through-cutting: Through-cutting cuts the packaging material.

● Scores: Instead of cutting across the entire material, scores leave indentations or partial cuts at individual stress points.

● Indentation: Indentation is similar to a die forming a fold line on the packaging material. Unlike an indent, an indentation allows the material to bend inward by having two parallel stress points. Having two stress points allows for greater flexibility in the material.

● Perforation: Perforation involves indenting a row of holes along the design material. The design is not separated from the material itself, but can be easily separated along the perforation line.

Each rule is constructed to accommodate the thickness of the material and the size of the recesses.

Steel rulers are hammered into the template by hand. Various foam and rubber parts are then glued to the mold.

These pieces help the die to bounce off the corrugated board during the production process.

The die cutter firmly presses the die into the cardboard to create the cut out shape (remember the cookie cutter).

Depending on the complexity of the package design, this cutout has several lines, creases and folds that are used to assemble the package by hand.

Excess material is collected and recycled in its entirety.

Creating individual molds for each package is an expensive task. However, over time, multiple orders for the same package are offset as a one-time cost.

Die-cutting Technology

Die-cutting remains very analog and manual in nature. Despite the technology used in the process, the fastest way to mass produce custom packaging is still to use manually constructed cutting dies.

The two most popular die-cutting techniques used in packaging are

1. Flatbed die-cutting.

Flatbed die cutting is made from a flat rectangular piece of hardwood (mold board) that contains a unique mold shape.

It involves the use of a cutting die, which is firmly pressed into the cardboard by a flatbed machine.

Flatbed die machines have small blank sizes, so they are not recommended for larger designs. However, they are capable of producing complex, detailed designs such as small cuts, tight cuts and cut scores.

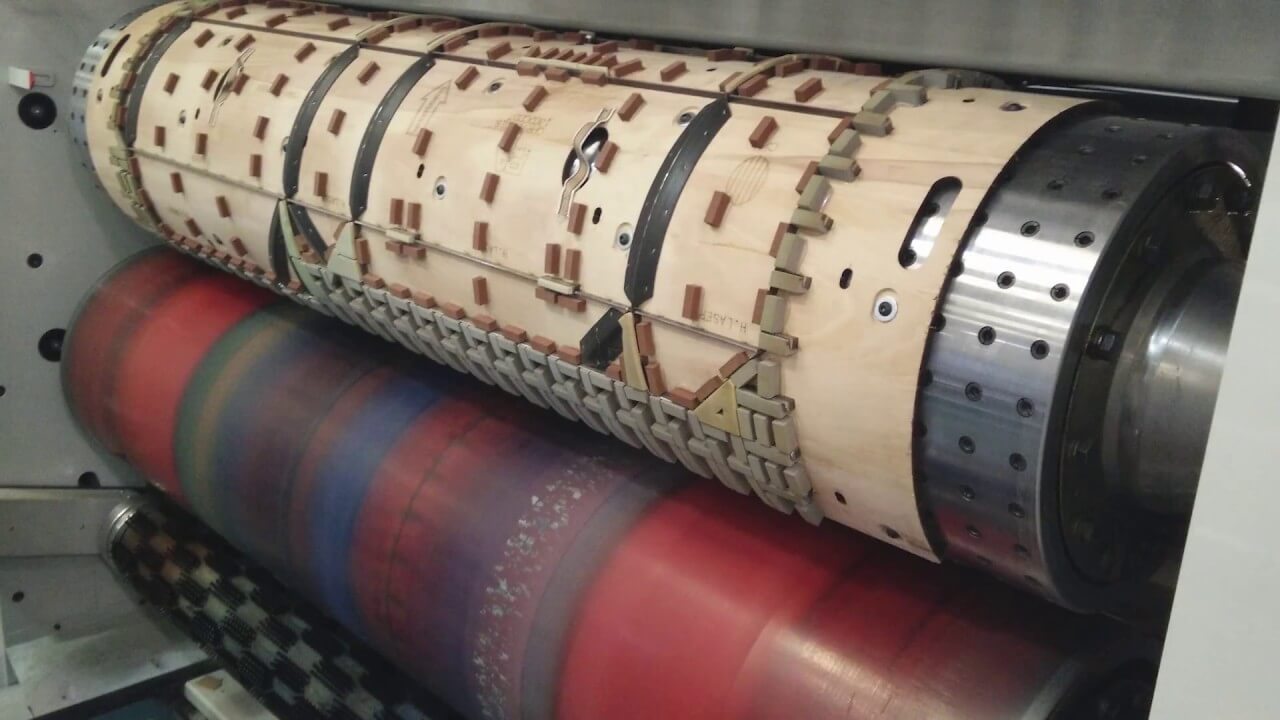

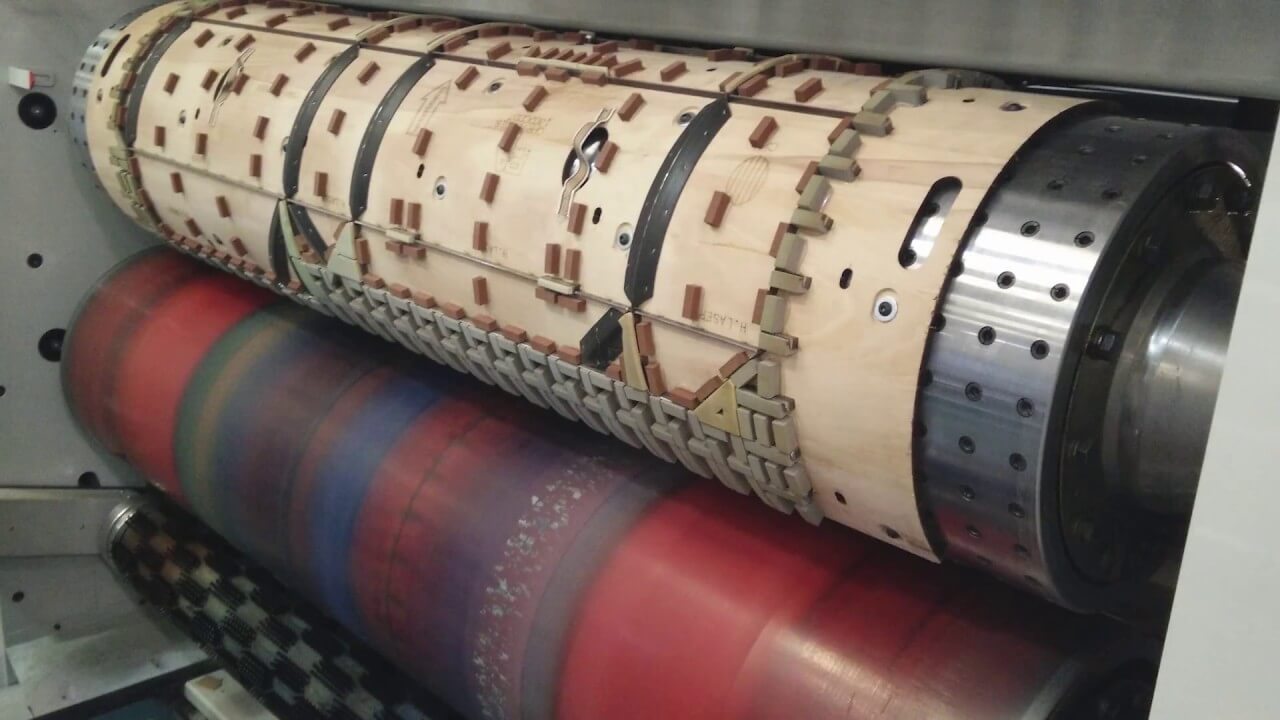

2. Rotary die-cutting.

Rotary cutting dies are made from cylindrical presses and roll over the cardboard rather than pressing downward as with flat die-cutting machines.

Rotary die cutting is a faster process and is ideal for high volume production of simple designs.

Some rotary die cutters can even perform two functions at once, such as embossing and laminating.

Despite producing higher volumes at faster speeds, rotary cutters are not always the best choice.

The type of technology/machine used depends on the design of the package and the desired functionality.

Digital die-cutting

Technological developments within the industry have led to the digitization of the die-cutting process. Traditional methods are still the most prominent and commonly used; however, it is now possible to die-cut packages without the use of steel knives.

These highly advanced machines use computer controls and lasers to cut instead of steel rulers.

Despite technological advances, digital die-cutting machines have limited capabilities.

They are a viable option for low to medium order volumes, but are not yet as fast as analog methods/machines.

Custom Packaging Examples

Regardless of size, material, fold or function, the die-cutting process can create virtually any type of packaging.

This freedom and wide range of packaging capabilities can be of great benefit to your company's fulfillment process.

There are several types of die-cut packaging available.

The European Federation of Corrugated Board Manufacturers ( FEFCO ) is the industry body that regulates the corrugated board industry in the UK and EU.

This organization has standardized corrugated packaging into digital codes. These codes have replaced complex code descriptions and are recognized throughout the UK and Europe.

FEFCO classifies corrugated box designs into eight categories.

These categories are the basis for die-cut boxes and can be modified in a variety of ways to create unique, customized packages.

The categories are as follows.

Commercial Rolls and Sheets

Commercial rolls and sheets are typically used to protect glass during storage and shipping.

Slotted Boxes

Slotted box types typically consist of a sheet of card with glued, stitched or taped manufacturer's joints closed. Most commonly, they are flat packed and require hand sealing during assembly.

A typical example of a slotted box is a shipping box.

Telescope-type boxes

Telescope-type boxes consist of multiple pieces of corrugated cardboard. They feature a lid and/or a bottom "telescope" on the body of the box.

Folding Boxes and Trays

Folding boxes and trays usually consist of a single board. The bottom of the box is hinged, forming all the walls and lid. Some additional features can be incorporated into a specific design, such as locking tabs, display panels, or handles.

Rigid Boxes

Rigid boxes consist of two separate end pieces with bodies. The box assembly requires stitching or similar fastening before it is suitable for use.

A two-piece product box is an example of a rigid box.

Sliding Boxes

Sliding boxes consist of several pieces of lining and sleeves that slide into each other in different directions. This FEFCO category also includes sleeve tubes for other boxes.

Glued Boxes

Glued boxes are usually easy to assemble. This style is essentially a flat piece of corrugated cardboard.

Interior Fittings

Interior fittings are separate components designed to be used with other box styles, most commonly dividers or separators to protect objects from each other, but may also have liners or padding.

The Finishing Touch in the Die Cutting Process

The die-cutting process enables truly unique custom packaging. will leave a lasting impression on the user.

But what if this luxurious style was taken further?

There are a variety of finishing techniques that accentuate the die-cut design of custom packaging. This emphasis on packaging design resonates with consumers and positively impacts their future purchasing decisions.

Take a look at some of the most popular finishing options and get the most out of your custom die-cut boxes:

Embossing

Embossing is a printing technique that raises the print higher off the surface of the packaging. The embossing machine creates an elegant finish that the user can not only see but feel.

The pressure of high temperature creates the embossing effect. A metal die is made (similar to a cutting die) that is then used to emboss the desired surface .

It is also possible to deboss - the opposite of embossing whereby the design is pressed underneath the packaging surface. This effect creates an indented look to the finish.

Whether it's an embossed or debossed finish, it is best coupled with high-quality die-cut packaging such as a rigid box.

UV Print

UV printing utilises ultraviolet curing technology during the printing process. Once the packaging material passes through the printer, it receives wet ink that is immediately exposed to UV light.

The exposure to the UV light dries the ink instantly, preventing seepage or the ink spreading in the process. This method provides sharp, vibrant printing that is the perfect accompaniment to a well-designed die-cut box.

Hot Stamping

Hot stamping is a finishing technique for custom packaging that uses high temperature for glueing foil or dry paint into the desired shape.

The finishes are pressed on with a die which transfers the heat. Hot stamping is great to pair with other finishing techniques, such as embossing or debossing. debossing.

This finish can work well for custom boxes, such as magnetic boxes.

Final Thoughts

The die-cutting process makes it possible to manufacture a variety of custom boxes. This method ensures design accuracy and also enables high volume production.

Diverse die-cutting techniques, machines and styles offer diverse packaging capabilities. This feature separates custom packaging from standardized packaging, presenting endless possibilities.

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery...

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery... The company has modern standard workshop and excellent staff. Since the establishment of our company in 2002...

The company has modern standard workshop and excellent staff. Since the establishment of our company in 2002... The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery....

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery.... Our company has established a nationwide after-sales service network, in all parts of the country can provide customers with fast and high-quality pre-sale and after-sale services...

Our company has established a nationwide after-sales service network, in all parts of the country can provide customers with fast and high-quality pre-sale and after-sale services... The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery...

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery...