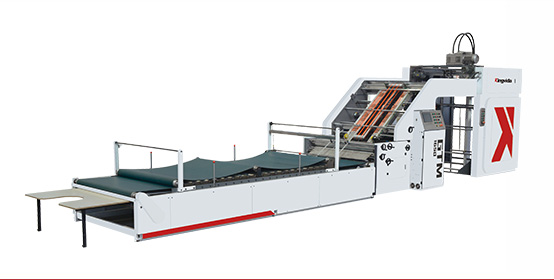

As this machine is a high-speed model, in order to effectively prevent glue throwing, it is required to use resin glue or starch cardboard glue.

The resin glue is briefly introduced as follows:

Resin glue is a new type of glue which is synthesized by adding resin additive to the original starch glue. It has the advantages of non-toxic, tasteless, green environmental protection, good adhesion, small amount of glue, fast drying, not easy to absorb moisture, and the machine runs at high speed without glue shedding.

1. With small amount of glue:

The amount of single-sided glue per square meter only needs 20-25 grams, and the cost is about 2 cents.

2. Quick drying:

It can be fully glued for 2-5 minutes and dried for 5-10 minutes. It can be firmly glued to white cardboard and kraft linerboard.

3. Not easy to absorb moisture:

Fully meet the cold storage and other humid environment storage and ocean transport export packaging requirements.

4. High speed glue shedding:

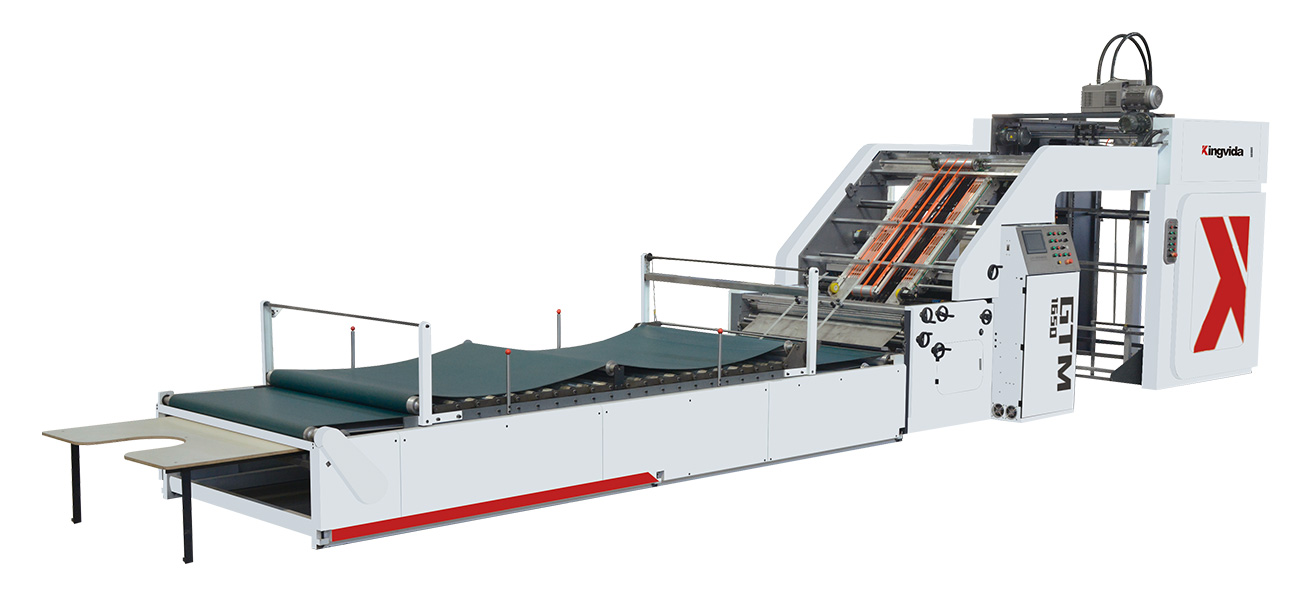

The laminating machine can work at a speed of 10000 sheets/hour.

5. Long shelf life:

Storage time at room temperature can reach more than one month.