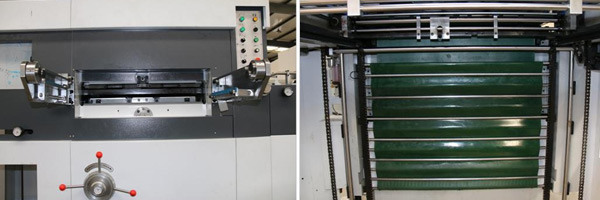

This machine realizes the automation of the paper feeding, die cutting, and paper delivery processes. Use the "human-machine interface" to display the machine's working speed, the number of processed sheets, the total running time and working status of the machine; realize dynamic monitoring of the input points, output points and various faults of the programmable controller, so as to troubleshoot and operate More convenient. (Optional) The preset technical device function can realize the stop of the air pump according to the preset number, and automatically mark; the electronic cam composed of the encoder and the programmable controller is accurate and reliable, and the adjustment is convenient. The frequency conversion governor is used to control the main motor and adjust the speed, with stable operation, low noise and energy saving. The machine also has automatic fault detection (including detection of double sheets, empty sheets, paper accumulation, falling paper, etc.), non-stop sampling functions, and high die-cutting pressure, high registration accuracy, and multiple sensors and safety protection devices. Ensure the normal operation of the machine and the safety of personnel.

The main drive system of the machine is equipped with pneumatic clutches, and a torque limiter (safety clutch) is installed on the main sprocket shaft to avoid injury and damage to operators and equipment due to emergencies, so as to ensure personal safety and equipment safety.

The machine is equipped with many safety protection devices in the whole machine. Once a person touches or enters the area, the alarm device will automatically alarm and the equipment is in a shutdown state.

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery...

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery... The company has modern standard workshop and excellent staff. Since the establishment of our company in 2002...

The company has modern standard workshop and excellent staff. Since the establishment of our company in 2002... The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery....

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery.... Our company has established a nationwide after-sales service network, in all parts of the country can provide customers with fast and high-quality pre-sale and after-sale services...

Our company has established a nationwide after-sales service network, in all parts of the country can provide customers with fast and high-quality pre-sale and after-sale services... The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery...

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery...