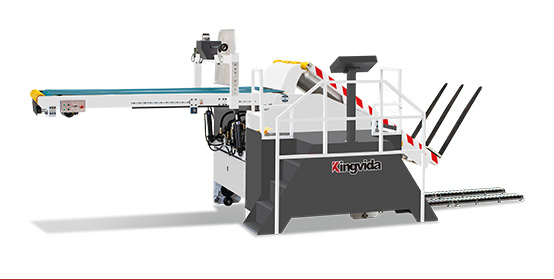

| Max. paper size | 1650*1200mm |

| Min. paper size | 650*400mm |

| Max. Die-cutting size | 1630*1180mm |

| Size inside the plate frame | 1660*1210mm |

| Die cutting plate size | 1680×1186mm |

| Paper processed cardboard | E、B、C、A、AB corrugated board with thickness 1.5mm—9mm |

| Min. wast size | 10mm(Depending on the arrangement of products, paper factors and operating factors) |

| Min. Bite paper edge | 6—12mm |

| Knife line height | 23.8mm |

| Feeding paper pile height | 500mm |

| Delivery paper pile height | 1300mm |

| Max. working speed | 5000sheets/h |

| Normal working speed | 4500sheets/h(Depending on the arrangement of products, paper factors and operating factors) |

| Die cutting precision | ±0.5mm |

| Die cutting pressure | 450T |

| Total power | 34KW(main power 18.5Kw, frequency control of motor speed) |

| Voltage | 380V、three phase、50HZ |

| Compressed air pump (Please match the freeze-dryer) | Volume 0.35 m3/min—Equipped by user |

| Pressure adjustable range | ±1.5mm |

| Dimensions | 9010*3465*2458mm(L*W*H) Operating platform is not included |

| Weight | 35Tons |

- Home

-

About Us

About UsMore than 20 years of deep accumulation of printing industry

Post-press equipment integration solution expert

Sales networks throughout the country

With high-end technical personnel and high-quality team The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery...

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery... The company has modern standard workshop and excellent staff. Since the establishment of our company in 2002...

The company has modern standard workshop and excellent staff. Since the establishment of our company in 2002... -

Products

- Corrugated Paper Die-cutting Machine

-

- C165 Automatic die-cutting and creasing machine with stripping station

-

- C165N Automatic die-cutting and creasing machine with stripping station

-

- C150 Full-automatic die-cutting&creasing with stripping station

-

- C150E Automatic die-cutting and creasing machine

-

- C130 Automatic die-cutting and creasing machine with stripping station

-

- C130E Automatic die-cutting and creasing machine

-

- KS1650 Full hydraulic semi-automatic paper feeding machine

- Feeder Feeding Automatic Die-cutting Machine

-

- MYQ1300 Automatic die-cutting and creasing machine with stripping

-

- MY1300 Feida automatic die-cutting and creasing machine

-

- MYQ1060 Automatic die cutting creasing machine with stripper

-

- MY1060 Automatic die-cutting& creasing machine

- Carton Forming Series

-

- K2500 Two piece folder gluer

-

- JAB Two piece folder gluer

-

- JAB Two piece folder gluer

-

- JAB A-type Two piece folder gluer

-

- JWD Semi-automatic folder gluer

-

- JWS-AB Type semi-automatic folder gluer

-

- JWY Press-type folder gluer machine

-

- JWG Bottom lock gluer

-

- JWR Semi-automatic folder gluer

-

News NewsMore than 20 years of deep accumulation of printing industry

Post-press equipment integration solution expert

Sales networks throughout the country

With high-end technical personnel and high-quality team The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery....

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery.... -

Service Support Service SupportRespected customers, if you have any questions or suggestions about the products or services of Kingvida Printing Machinery Co., Ltd., please feel free to call the company at

0315-6505268。 Our company has established a nationwide after-sales service network, in all parts of the country can provide customers with fast and high-quality pre-sale and after-sale services...

Our company has established a nationwide after-sales service network, in all parts of the country can provide customers with fast and high-quality pre-sale and after-sale services... The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery...

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery... -

Contact Us Contact UsRespected customers, if you have any questions or suggestions about the products or services of Kingvida Printing Machinery Co., Ltd., please feel free to call the company at :

0315-6505268 。 -

- 中文版