This machine is newly designed by our company based on the bending and warping of the paper, combined with our company's years of production experience in semi-automatic die-cutting machines and full-automatic die-cutting machines, and combined with the questions raised by a large number of customers. Wide suitable for more customers. The paper feeder adopts chainless transmission, which is easy to operate and more humane. It is convenient for manual one-key conversion and adjustment. Hand-automatic integration means that it has two paper feeding methods, manual and automatic. The model is developed according to the customer's product requirements.

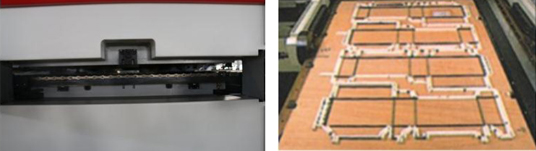

When the paper quality is good, the automatic state can be adopted, and the speed is high and easy to use. When the paper quality is poor, the manual mode is adopted, and the conversion between the two is flexible and fast. The range of usable paper is wide, which can better adapt to the customer's product diversity and broaden the use range of the machine. It is a widely applicable model designed according to the actual needs of customers. The MY1300 manual automatic integrated machine produced by our company discards the traditional chain for the transmission part of the paper section, and uses a large amount of synchronous belt and gear components at any cost.

The fine-tuning mechanism can adjust the paper arrival time without limitation. The left and right movement mechanism of the paper feeding table is electrically controlled, with a large adjustment distance. It has the function of automatic centering when the paper is changed. The manual and automatic shift position is changed by one key. When the paper is automatically pressed, the upper roller presses the paper, and the lower roller does not move. The machine runs more Stable, smoother paper feeding, fast die-cutting speed; manual reciprocating movement for the lower point roller, large stroke, more suitable for curved paper, and equipped with a stop rule, manual paper feeding is simpler than ordinary semi-automatic paper feeding Convenience. Switch the electrical control, the cylinder will automatically switch after the switch is turned, without manual adjustment. Feida is powered by an independent servo motor to track the paper feed time of the host, and installs two motors to control the forward and backward movement, which can be manually adjusted. It is automatically adjusted when the hand is automatically switched, and when it is set to automatic, the feeder automatically adjusts to the maximum paper position and drops to the preset height. The customer fine-tunes the feeder position according to the size of the paper. When switching to manual, the feeder moves to the rear, rises to the highest position, and stops the paper feeding action, freeing up a lot of space for personnel. The entire conversion process only needs to manually remove the paper flipping board, and all the rest are automatically controlled, saving a lot of time, manpower, high efficiency and high degree of automation.

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery...

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery... The company has modern standard workshop and excellent staff. Since the establishment of our company in 2002...

The company has modern standard workshop and excellent staff. Since the establishment of our company in 2002... The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery....

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery.... Our company has established a nationwide after-sales service network, in all parts of the country can provide customers with fast and high-quality pre-sale and after-sale services...

Our company has established a nationwide after-sales service network, in all parts of the country can provide customers with fast and high-quality pre-sale and after-sale services... The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery...

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery...