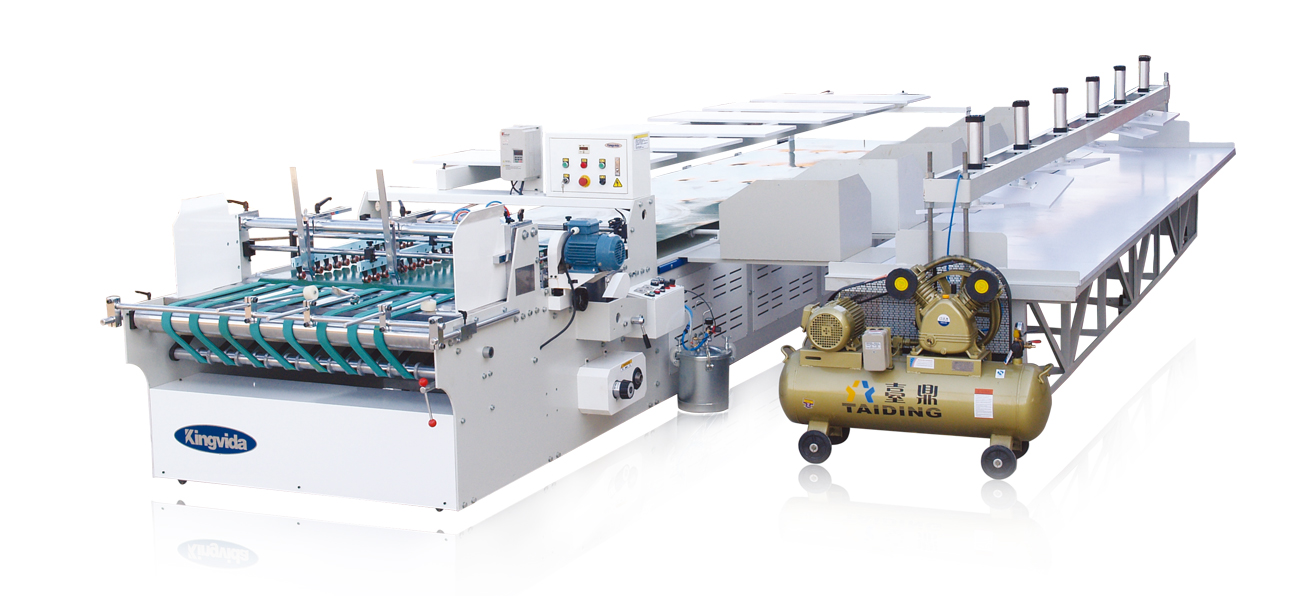

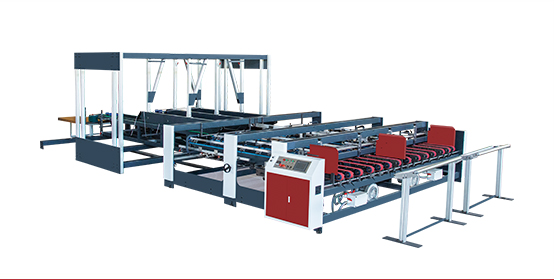

JWD Series semi-automatic folder gluer is mainly used in the corrugated box and carton gluing process of color printing and packaging enterprises.

Feature1: High speed edge grinding to ensure that the box is firmly gluing. Solve the problem of customer return due to glue opening.

JWD Series semi-automatic folder gluer using unique diamond or sand wheel high speed edge grinder can polish off the UV oil layer and laminating layer at the gluing position of the carton to realize the gluing between the papers. Fundamentally solve the problem of glue opening of glossed and laminated paper, greatly reduce the cost of glue.

Feature2:The machine can evenly gluing. Manual gluing with brush has many drawbacks, and need to employ skilled workers, but the quality is not easy to control.

JWD series of semi-automatic folder gluer machine, simple and practical gluing method by adjusting the gap between the gluing wheel and the scraping plate to adjust the amount of glue, so that the amount of glue is always uniform, reducing the dependence on skilled workers.

Contact us.

Feature3: Glue spraying function can process various shapes and complex cartons.

JWD series of semi-automatic folder gluer machine can process double-piece carton gluing, four-angle adhesive heaven and earth cover box, adhesive bottom box and other types of paper packaging, improve the working efficiency of processing various complex cartons.

Feature 4: The machine can processed corrugated box and cartons that can not be processed by fully automatic machines.

JWD series of semi-automatic folder gluer machine can process color corrugated box, with window box , thick paper box. This machine adopts the optimized design to paper feeding, which is convenient to transport all kinds of corrugated boxes and cardboard boxes, especially corrugated boxes, which not only has fast speed, but also ensures the gluing accuracy of corrugated boxes.

Fast speed and high efficiency.

JWD series of semi-automatic folder gluer machine organizes less people together to form a gluing assembly line, which will be suitable for mechanical work done by machinery. Correcting corrugated box skew is done by people, that is, good management and ensure the accuracy of gluing box, greatly improve human efficiency.

he equipment can reduce production cost. Packaging factory price competition is becoming more and more fierce, how to reduce costs and improve quality has become the key.

The use of JWD series of semi-automatic folder gluer machine to make the polished paper gluing, with very cheap glue can ensure that the corrugated box is firm, especially UV glossed and laminated carton, with ordinary glue can be glued firmly.

Feature 7: Simple operation, no need experience worker. Some paper products factories, there will be production off-season, operators have nothing to do, production season lack of skilled workers.

JWD series of semi-automatic folder gluer machine operation is extremely simple, the efficiency of workers is multiplied, the changing of order is fast, even if no experience of new employees can operate. Customer can control the production season and light season freely.

Feature 8: This equipment has small investment, less depreciation, less malfunction, less occupation, no risk and practical.

The semi-automatic folder gluer machine has the advantages of simple structure, low price, less occupation and labor saving, which saves you valuable space and money. In addition, the design principle of our equipment is practical, and the main components such as electrical appliances and belts are imported. Make machinery economical and durable.