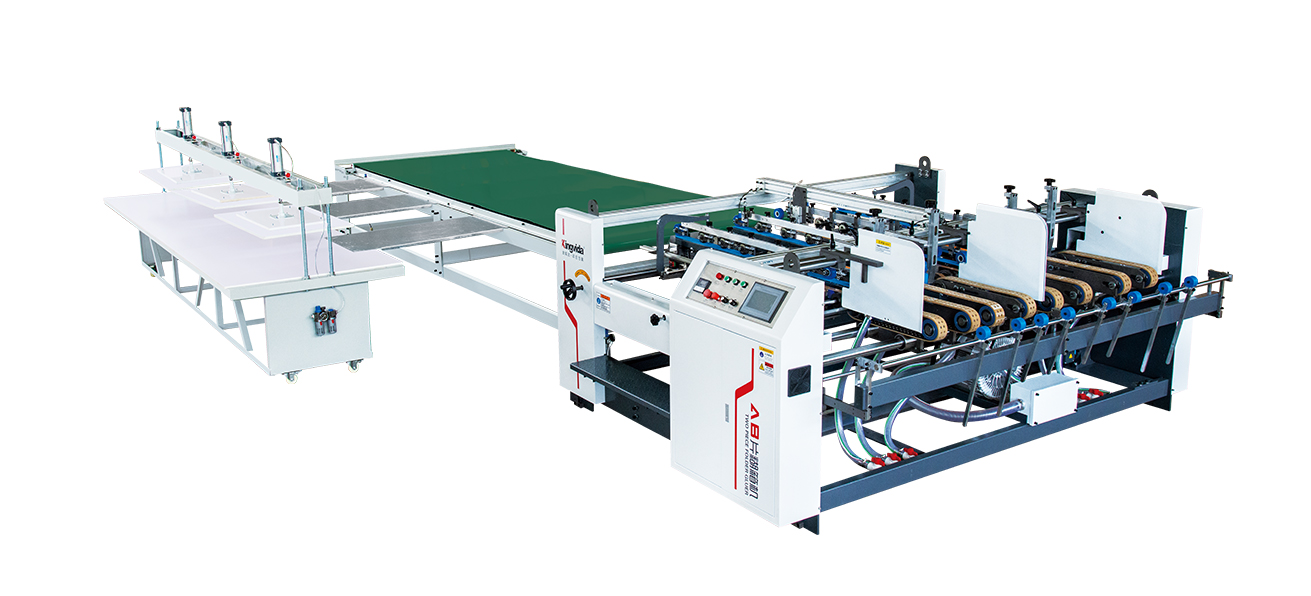

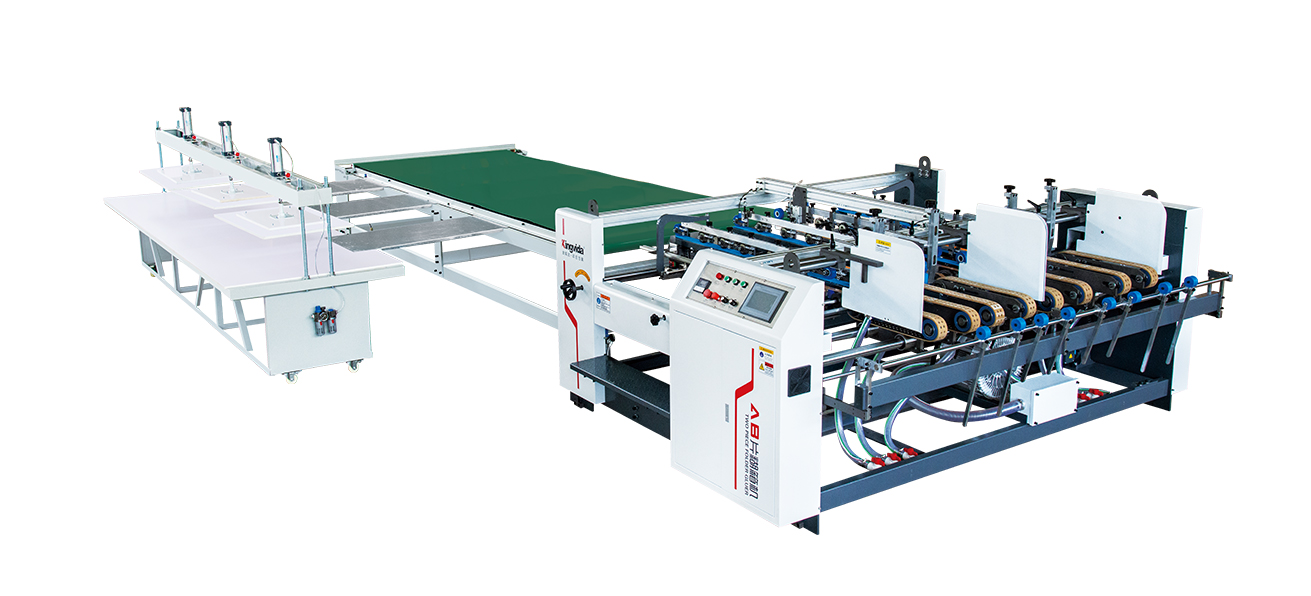

A carton box forming machine is a machine used to produce corrugated cardboard boxes. The machine takes flat sheets of corrugated cardboard and forms them into boxes of various sizes and shapes. The process is automated and can produce a large number of boxes in a short period of time, making it a cost-effective solution for manufacturers and businesses that need to produce large quantities of boxes.

Two piece folder gluer

Workflow

The process starts with flat sheets of corrugated cardboard, which are fed into the machine. The first step is to score the cardboard along the desired fold lines. Scoring is the process of creating a weakened line in the cardboard to make it easier to fold. The scoring is done by a scoring blade, which is attached to the machine and makes a series of cuts in the cardboard.

Next, the cardboard is fed through a series of forming rollers, which shape the cardboard into the desired box shape. The rollers are designed to bend the cardboard along the scored lines, creating a series of folds that form the sides of the box. At the same time, glue is applied to the flaps that will be used to secure the box closed.

After the box has been formed, it is cut to size by a cutting blade. The cutting blade is a large blade that moves across the surface of the cardboard, cutting it to the desired size. The cutting blade is attached to a guide rail, which ensures that the cuts are made accurately and consistently.

Once the box has been cut to size, it is moved to the folding station. The folding station is where the flaps of the box are folded over and secured in place. The folding is done by a series of rollers, which apply pressure to the flaps and fold them over. The rollers also apply glue to the inside of the flaps to secure them in place.

Finally, the completed boxes are stacked and loaded onto a pallet for shipment. The boxes can be stacked in a variety of configurations, depending on the needs of the customer. Some machines are equipped with automated stacking systems, which can stack the boxes in a neat, orderly fashion.

In summary, a carton box forming machine is a machine that takes flat sheets of corrugated cardboard and forms them into boxes. The process involves scoring the cardboard, shaping it into the desired box shape, cutting it to size, folding the flaps, and securing them in place. The completed boxes are then stacked and loaded onto a pallet for shipment.

Are you interested in learning more about carton box forming machines for sale? Contact us today to secure an expert consultation!

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery...

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery... The company has modern standard workshop and excellent staff. Since the establishment of our company in 2002...

The company has modern standard workshop and excellent staff. Since the establishment of our company in 2002... The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery....

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery.... Our company has established a nationwide after-sales service network, in all parts of the country can provide customers with fast and high-quality pre-sale and after-sale services...

Our company has established a nationwide after-sales service network, in all parts of the country can provide customers with fast and high-quality pre-sale and after-sale services... The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery...

The outstanding Tangshan Kingvida Printing Machinery Co., Ltd. is a professional manufacturer of printing and packaging machinery...